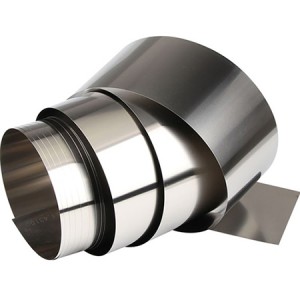

3J01 Bar /Strip /Sheet

Common Trade Names:3J1, ЭИ702,36HXTЮ,Ni36CrTiAl

3J01 alloy is an Fe-Ni-Cr austenite precipitation reinforced high elastic alloy.After solid solution treatment, it has good plasticity, low hardness and easy processing and forming.High mechanical and elastic properties were obtained after solid solution or cold strain aging treatment.

| Alloy | C | Mn | Si | P | S | Ni | Cr | Ti | Al | Fe |

| 3J01 | ≤0.05 | ≤1.00 | ≤0.80 | ≤0.020 | ≤0.020 | 34.5-36.5 | 11.5-13.0 | 2.70-3.20 | 1.00-1.80 | Ban |

|

Density

(g/cm3)

|

Resistivity (L2 - m) |

Vickers

hardness

(HV)

|

Modulus of elasticity(E/MPa) | Shear deformation(G/MPa) | Magnetic frequency(K/106) |

|

8.0

|

1.02

|

400-480 | 186500-206000 | 68500-78500 | 150-250 |

| Status | Thickness/diameter (mm) | Tensile strength σb/MPa | Elongation As % |

| annealing | 0.20~0.50 | ≤981 | ≥20 |

| Cold drawn | 0.20~3.0 | ≥981 | - |

3J01 Available Products in Sekonic Metals

Why 3J01?

3J01 alloy has the characteristics of high strength, high elastic modulus, small elastic aftereffect and hysteresis, weak magnetism, good corrosion resistance and thermal stability, and can work under higher temperature, greater stress or corrosive media conditions.

3J01 Application field:

Used to manufacture all kinds of aeronautical elastic sensitive elements and parts resistant to nitric acid or other corrosive media, such as film boxes, diaphragms, bellows, transfer rods, baffles and other elastic structures.